Photo by KJ Brix from Pexels

In the vast landscape of industrial automation, one component has solidified its crucial role: the electric rotary actuator. These devices hold substantial sway despite being less known to those outside their specific industries. They are pivotal elements within a broad array of sectors, spanning from manufacturing to healthcare, and are central drivers of technological advancement.

Understanding Electric Actuators

Electric actuators are designed to generate rotary motion from an electrical input. The ability to produce this kind of movement is essential in various sectors, given that these actuators can provide precise, controlled positioning and movement. Electric actuators can operate at varying power levels depending on the application’s requirements. This versatility makes them appropriate for various tasks, from light to heavy-duty industrial operations.

While the design, function, and applications of electric actuators can vary significantly, their core objective remains consistent: the conversion of electrical energy into mechanical action. This singular capability is especially crucial in automated industrial systems where the emphasis is on precision, reliability, and efficiency. The role of these actuators in such systems underscores their importance in modern industrial operations.

Industrial Applications of Electric Actuators

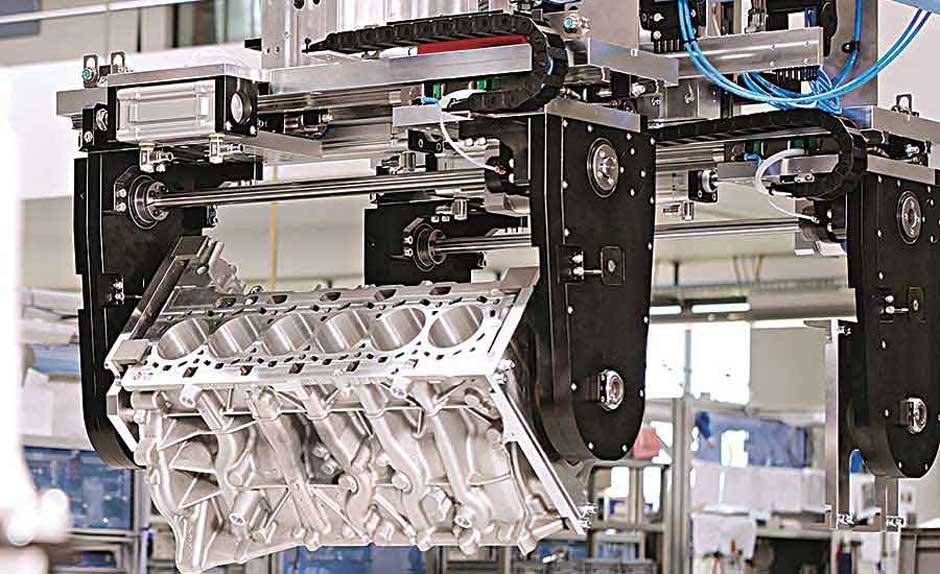

In the field of industrial automation, electric actuators have demonstrated their indispensability. They have been incorporated into a multitude of machines and systems, facilitating various automated functions. These include but are not limited to, production lines, robotics, and conveyor systems. Through these applications, they enable operations such as the opening and closing of valves, positioning sensors, and moving machine components.

These actuators have also found applications in less obvious sectors. In the pharmaceutical industry, electric actuators assist in the production of medicines. In the automotive industry, they are integral components of assembly lines. The contribution of these actuators to enhanced productivity and quality in these sectors further underscores their reliability, precision, and overall value.

Key Considerations in Selecting Electric Actuators

When it comes to choosing an electric actuator, there are several critical factors to consider. These include matching the torque and speed of the actuator to the application requirements. An equally important factor is the actuator’s durability and its resistance to the operating conditions it will be exposed to.

The physical dimensions of the actuator, including its size and weight, should be suitable for the intended application. Other key considerations include the cost of the actuator, its maintenance requirements, and its compatibility with the existing system. All these factors play an essential role in determining the appropriate actuator for a given application.

The Future of Electric Actuators in Industrial Automation

The trajectory of technological advancement signals an increasingly prominent role for electric actuators in industrial automation. With the relentless pace of innovation, these devices are expected to keep pace and evolve, becoming even more vital to the operation of automated systems. Their ability to provide precise and reliable action is expected to remain critical, and their advancement will likely yield new capabilities and applications. Furthermore, as more industries embrace automation, the demand for these versatile devices is likely to surge.

Bottom Line

All in all, the primary function of an electric actuator is to convert electrical energy into mechanical motion. As a result, this transformative ability makes it an indispensable part of numerous mechanized processes.

Electric actuators have established themselves as a pivotal component in the realm of industrial automation. Their ability to transform electrical energy into precise, controlled mechanical motion has made them indispensable across various sectors. As we look ahead, their importance is set to increase even further with continuous technological advancements. The future of these devices is not just about their mechanical and electrical capabilities but also their energy efficiency, durability, and cost-effectiveness. As these aspects continue to improve, the role of electric actuators in driving the future of industrial automation will only become more crucial. It’s clear that these unsung heroes of automation are set to take center stage in the industry’s future.