The manufacturing industry has come a long way. From the time beings when manufacturing things was manual to the era of automation, people have seen everything. Skilled mechanists used to spend months building a part of an instruments. And now everything has become labor-free.

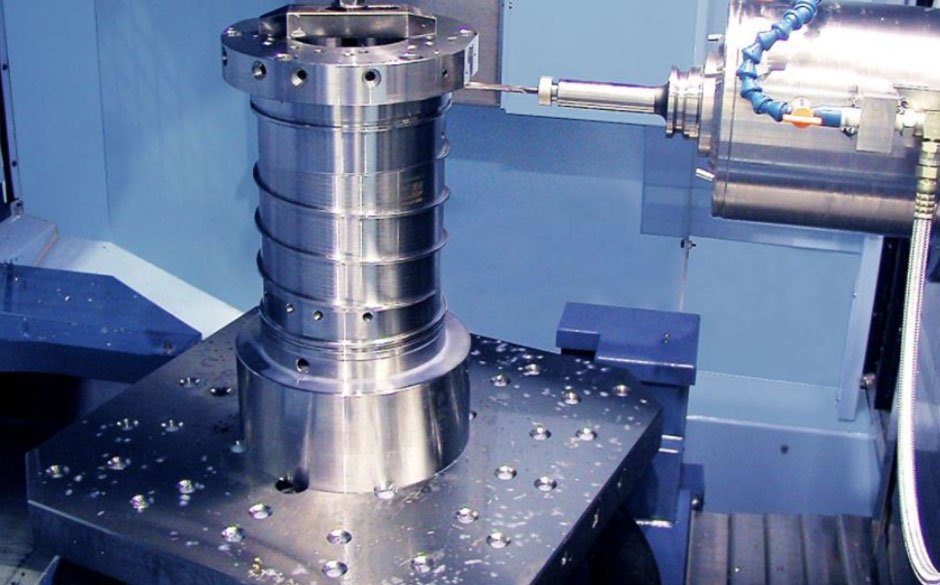

Metal fabrication was a laborious work. In crafting a single piece into a specific shape you need an advanced level of precision. The advent of Computer Numerical Controlled machines has revolutionized the metal fabrication industry. In this article, we’ll explore how CNC milling is benefiting the metal industry. We’ll also look into the recent advancements in the applications of metal milling. Before diving into the details of benefits and applications, let’s read what CNC machining is.

CNC Machining

Computer Numerical Controlled (CNC) Machining is also known by other names like Machining, automation, g-code, lathe, plasma cutting, and many more. CNC machining is basically a manufacturing process. In this process of manufacturing, computer software is used. The computer software is installed in manufacturing machines. The movement of tools of machines is according to the information of software. This way all the cutting, shaping, and processing happens with the computerized control system. You achieve high-grade precision, accuracy, and specifications. Metal CNC machining is now the talk of the town. Metal fabrication using Lathes has become a part of the manufacturing industry.

CNC Machining in the Metal Industry

Metal fabrication is a part of every major industry. From aerospace to automotive to medical and electronics, you’ll see metal fabrication is an integral part of them. There’s a brief overview of each industry that fabricates metal with CNC machining.

-

Aerospace and aviation industry

In the aerospace and aviation industry, CNC machining is used to intricate the landing gears, engines, and many other parts of the aerospace-like structure. You require a high level of accuracy and tightness in this industry. So, this much precision can only be achieved with an automated tool like CNC machining.

-

Automobile industry

The automobile industry is one of the largest industries of current times. And the production units are massive. The production rate is ever more massive. For the mass production of various components of automotive, CNC machining is a perfect choice. In building lightweight cars, engines, or gears, or you want to make driverless vehicles, Lathe will never disappoint you. The complex shapes and intricate designs can be made in no time with the CNC services.

-

Electronics industry

More than 80% of things in our homes are electronic nowadays. From circuit boards to ovens, hair dryers, coffee makers, washing machines, LEDs, and electronics are everywhere. Only CNC machining can handle this much production load. The dedication to electronics and small detailing can be done finely with CNC machining.

-

Medical industry

The medical industry is very large even in third-world countries. All medical equipment and instruments are manufactured with CNC machining. You can’t take any risk in the precision of medical tools. Computer-controlled machining is used to build dental implants, surgical tools, cosmetic implants, orthopedic implants, and in so many more things.

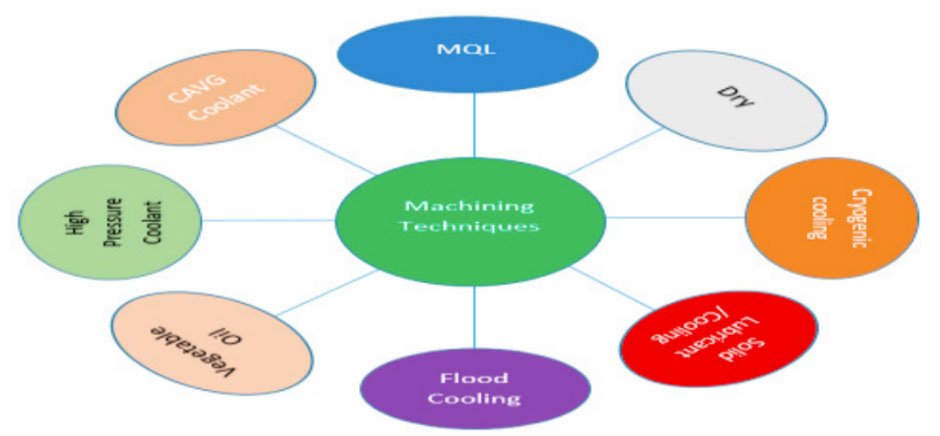

Manufacturing techniques in CNC machining

Globalization has forced everyone to be part of the race to make the best instruments in the world. CNC machining has made the manufacturing process less expensive. You only need to invest for one time in the computer system installation in your machines. And you’ll get cost-effective, high-end products, with a high accuracy level. The cost of labor will also be reduced automatically. Now, CNC machining has become cheaper than the time it was introduced. And everyone can access it. There’s competition in the market to make the best products. Different companies use different techniques to manufacture the same product. The accuracy of both is the same but the process is different. There are following manufacturing techniques are used in CNC machining:

- Machining with Minimum Quantity Lubrication technique (MQL)

- Machining with solid lubrication

- Machining with cryogenic cooling system

- Compressed Air/Vapor/Gas as a coolant in machining operations (CAVG)

- Machining with high high-pressure coolant system

- Vegetable oils as lubricants

- Dry machining

- Wet/flood cooling

Benefits of CNC machining in Metal Fabrication

Metal fabrication is not as easy as fabricating a piece of cloth. It is a complex process and requires more attention. If you use traditional methods in fabricating a metal, you end up with products with varied end results and work is also laborious. So, it’s better to take advantage of the technology and use the best one for the best results. We can write articles on the benefits of CNC machining in metal fabrication and how it has proven best for our lives. But here only the majority of them are briefly discussed:

-

Enhanced accuracy

CNC milling generates similar products to an instrument if an instruction is given to the software. Accuracy and precision are the two key features of CNC milling. The product’s quality and customer’s customization requirements are never bargained for.

-

Enhanced manufacturing speed

The CNC milling machines can work 24/7.

-

Reduce labor cost

You don’t need the operator 24/7 to run the system. So, labor costs are automatically reduced this way.

Cons of Laser cutting

However the pros of laser cutting technology always outweigh the cons, but we can’t take our eyes off the cons. The major cons of this are the following:

- The initial installation of the CNC machining system is very high. Everyone can’t afford it.

- The repair cost of the system is also high.

- You need an expert to operate the system. The expert should be highly skilled in this field. A minor ignorance could cost you a loss.

Advantages of CNC Machining over conventional techniques

The advantages of CNC machining over the conventional methods of manufacturing things are overweighing the weight balance. With no doubt, CNC milling has greater efficacy and consistency. The few major advantages of milling will be discussed here

-

Minimal error chances and waste of material

With a CNC milling manufacturing unit, the chances of errors in the product are near zero. The whole system is computer-based. There are no human errors and little to no errors in any step of production. Not only that, CNC milling makes sure that it produces minimum waste material. It is a very environment-friendly process. The optimized processes generate little scrap and that can be reused. In the traditional methods of manufacturing, you experience high chances of errors and a high amount of waste at the end of the process.

-

Reduced manufacturing time

One of the key characteristics of CNC machining is making objects in as much less time as possible. This not only saves the time of the manufacturer but also enhances the profitability. Mass production can be achieved in less time and efficiency, and quality is not compromised at all. It takes ages to complete a single part of an instrument if you use manual methods. And manual manufacturing is also not cost-effective at all. You put in more effort and get less reward.

-

Higher flexibility

A single CNC machine can make a wide range of designs of different shapes, geometries, and over different metals easily. Metal fabrication requires fine detailing and neat finishing. Most of the time customers love to customize their objects, and all of it can be done with Lathe.

Moreover, unlike the traditional methods where you need lots of labor to make changes in a design. With computerized work, redesigning is much simpler with no extra work and no need for extra tools. This way, you can easily meet the market demands, as we are living in an era where fashion changes every other day.

-

Fewer risks of calamities

No human intervention is involved in operating the machines of CNC. It means no risk of human calamities or injuries is involved. The safety is the prime concern of every industry. As you know, in the traditional methods, the risks of accidents are quite high. One day or other, news comes of such an incident. So, it’s always better to take care of yourself first than the work.

-

Works best for a wide range of metals

When it comes to making a vehicle or medical instrument or anything, it does not form a single material. Only CNC milling provides services where you can use versatile materials under one machine. CNC machining has the ability to work for varying levels of density and have the ability to handle diverse materials. Be it aluminum, iron, steel, titanium, or any metal of your choice, everything can be handled with care. This broad range of material handling ability makes it liable to use in all kinds of industries.

CNC Machines Available for Metal Fabrication

There are five different types of CNC machines which can be used for the metal works. Each has its own advantage but the result of each is of top-notch quality.

-

CNC Milling Machines

The milling machines usually have rotary cutters. The metal piece could be shaved, or sliced in horizontal and vertical directions. Both 3-axis and 4-axis machines are available in the milling category.

-

Drilling CNC machines

The purpose of the drilling machines is to make holes in the metal material. Both pecking and interrupting modes can be used. Automation makes the drilling accurate and in position.

-

CNC Lathes

Lathes are usually used when you have to cut objects into a specific symmetrical shape like a cylinder or sphere. Circles can also be made with a Lathe.

-

Plasma Cutter CNC

CNC machining in the category of Plasma Cutters uses a plasma torch. With the help of torch, a metal sheet is cut down into 2D shapes.

-

CNC Grinders

As the name indicates the grinders grind the metal into the specific shape. A rotary sheel performs this job. Using Grinders is easier than milling and lathes.

The famous CNC machine available for machining in metal fabrication is Kanyana’s 4-axis CNC Machine.

Conclusion

If you are a newbie in the field of computer-based milling or you are a seasoned expert, we assure you that this field is highly rewarding. Understand the working process of each machine with full enthusiasm and you’ll get the desired results in no time.

At Zintilon, we provide the services of customization of metal sheets. The facilities are available online. The lead time is only one day. So, go search Zintilon and get the services.