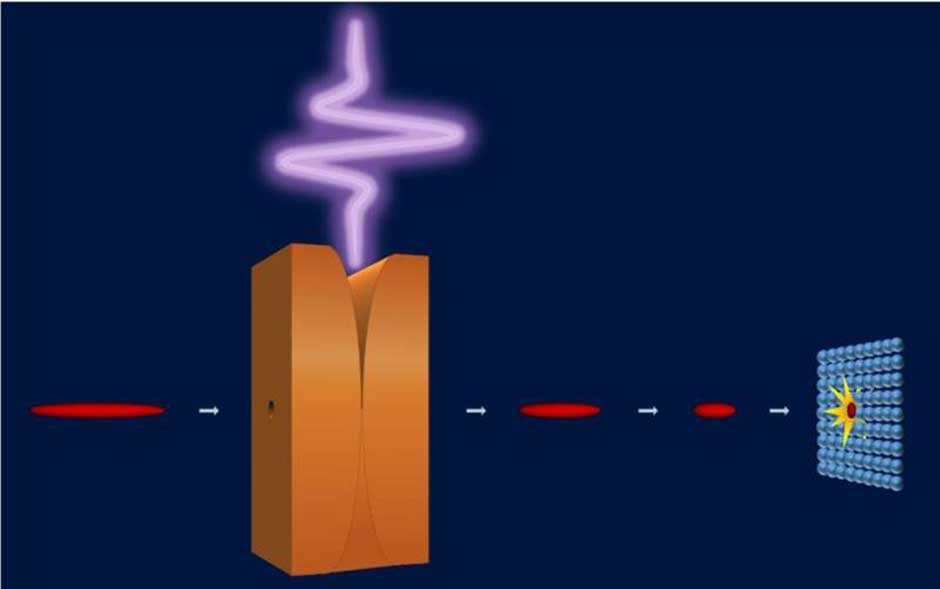

Stacked lasers are categorized according to the length of their pulses. A modulator controls the number of pulses per second. Therefore, each pulse has a precise time length, known as pulse duration, pulse length, or pulse width.

The pulse duration is the time between the onset and conclusion of a pulse. There are various modulating methods to pulse laser beams. Q-switching, gain-switching, and mode-locking are a few examples. The higher energy peaks are achieved with shorter pulses.

There are two operating modes for LASIT Laser marking machines for metal cans: pulsed or continuous. When operating, this machine employs either a continuous-wave laser or a pulsed laser. A constant flow of energy is produced by continuous-wave lasers, making them suitable for laser cutting and laser welding. A laser pointer is an example of an uninterrupted laser beam.

With pulsed lasers, the laser beam is pulsed at regular intervals, accumulating high peak power. When the laser beam is released as pulses that last a certain period, it is known as a pulse. It is used for many applications, such as laser marking.

Even if continuous-wave lasers seem more powerful than pulsed lasers, this is not always true. The power indicates the average laser power, and the average laser power of pulsed lasers is usually lower, even if the peaks are higher.

A continuous 6,000 W laser continuously releases 6,000 W of laser power, for example. In contrast, a 100 W pulsed laser can release 10,000 W pulses each time.

FlyMOPA Laser Marker

The MOPA fiber laser marker has a 1064 nm wavelength and can control the pulse duration, making it possible to achieve impossible results with traditional fiber lasers, especially on color or plastic laser marking.

Laser Marker for FlyPico.

The fiber laser source in the Powermark FlyPico laser is renowned for its precision in post-marking treatments such as citric or nitric passivation cycles. It is the first choice when it comes to post-marking treatments, like the Powermark FlyPico laser.

Medical Devices, Home Appliances, Jewelry adn Business are being increasingly marked using this laser.

How does the power of the laser affect its wattage?

When it comes to laser processing power, the depth and bearing of the markings have no bearing on the processing speed. Contrary to popular belief, the laser wattage doesn’t determine the depth and bearing of the markings.

Look at the various incisions made with the same laser source at various power levels. Here, it is clear how power affects laser marking speed.

The range of laser pulses that can be generated using these types of lasers. In conjunction with the preceding sentence, it reveals that the types of lasers are also known as the types of beams.

Using a modulator, you can control the number of pulses per second of a pulsed laser. A pulse has a particular time, known as pulse duration, pulse length, or pulse width. A pulse lasts from the beginning to the end of its turn. Q-switching, gain-switching, and mode-locking are a few examples of modulating techniques. A higher energy peak occurs with short pulses.