Like any other types of home projects, it is a good starting point to run some figures and plans to determine whether or not the project will fit in your budget.

Getting your plumbings repaired should not be a passive exercise because there are some factors that you might want to be keen about, or you will end up falling victim to nasty companies that might take advantage of you. Read the tips below on how you can avoid their traps.

1. Our price is more competitive

When a company claims they are cheaper than the other, you should be curious. Companies that usually offer far-fetched price are more likely to deceive you by providing an estimate for a different job and give you nasty surprises after. Before trusting their words, you should do your research to figure out if they are telling the truth. It’s also good to ask as many questions to prove if they are the best people to do the job. Also, while it may sound time-consuming, comparing prices with other companies helps.

It will give you a clear picture of the budget in your head. As a tip, a trusted pipe relining company offers services with prices within the market range. Nothing less, nothing more, unless maybe the job would take longer than expected; They also provide a quote estimate of the project based on what they found out and explain the cost involved.

2. Our material is of good quality

Some relining companies claim they’re using the best material there is, but if it’s not Australian Watermarked approved, forget about it. As of 2 years ago, it became a legal requirement for reliners to use Watermark approved materials and products. Anything outside that guidelines is considered unsuitable for use within Australia.

Certified pipe relining solutions professionals use only the best quality materials that are safe for use for plumbing and drainage. They will never compromise the reputation of their company for a substandard product and materials.

3. We are certified contractors

A lot of companies fancy telling people they are expert in relining, but the truth is they are inexperienced installers, or they outsource their jobs. That is why you can find some Sydney relining solutions companies that offer higher sewer pipe relining costs compared to others because they hire licensed contractors to do the job for them.

When you’re uncertain about the credibility of the company you are dealing with, you might as well check their website for customer feedback and some photos of their actual works. Certified contractors also provide product guarantee for every relining job. If the company you are dealing with doesn’t have this inclusive of their services, don’t waste your money. Find someone else who is committed to not only giving you a one-off service but all-out support.

Now that you learned the possible things that some companies might claim to get your money, let us discuss the things that affect the cost. It will give you enough idea where your money would go when you go for relining. Understanding these factors will prevent you from paying unnecessary charges and know what to expect during the repair.

Factors that affect the pipe relining cost Sydney

1. Condition of the existing pipe: If the relining requires much longer hours of procedures such as clearing with a high-pressure water jetter, this will affect the price. Drains must be free from any types of clogs and debris before relining to ensure cohesion between the liner and the existing pipe. In cases of broken or displaced pipes, additional work to prepare the pipeline for relining may be needed, which implies an extra cost. While it doesn’t sound good on your pocket, it is worthwhile to take these steps to get the best possible, long-lasting result.

2. Size and the length of pipe: Licensed contractors can reline different sizes of pipes. As you can imagine, this heavily affects the cost the same with the length. Once the size and length of the pipeline in question are determined, contractors will be able to give you the price per meter.

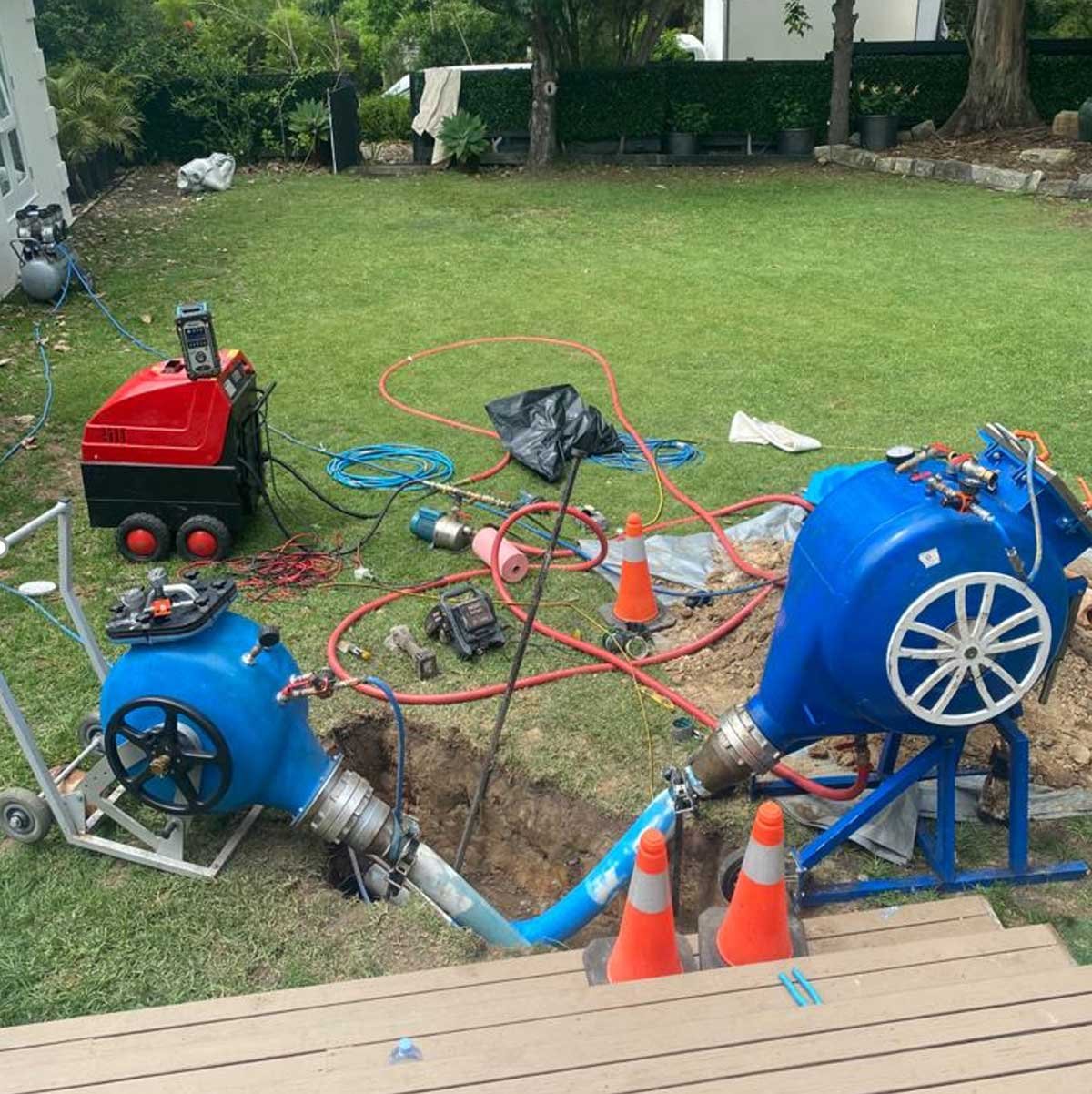

3. Location: Not surprisingly, location is another factor that will impact the pipe relining cost. The equipment used in relining is generally big and heavy, and transporting it to the location can be difficult with bare hands. So it will take additional time and require more staff to help bring it there.

4. Accessibility: Although pipe relining is a trenchless technology, the reality is that sometimes plumbers have no other choice but to work on small trenches and holes to create an entry point for the equipment and materials. As this will take additional time, labour and more materials, a small labour fee will be added.

5. The number of joints: The number of joints within the pipeline is one of the main reasons why drain camera inspection is necessary to determine the cost. So if you notice joint patches in the quote, you should ask. You can also check the drain camera footage that the plumber has taken to verify this.

6. Materials: There are several pipe relining companies out there, but not are equal. There are some that use top of line materials, while others use substandard quality, and both of these affect the cost. As discussed above, you should be curious about the materials the contractors will be installing in your plumbing. Quality speaks a lot when we talk about lifespan and safety. Australian Watermarked approved products have passed the test for quality and safety. On the other hand, low-quality materials are cheaper, but they are risky to use.

7. Procedures: There are three main methods used in relining, explained below.

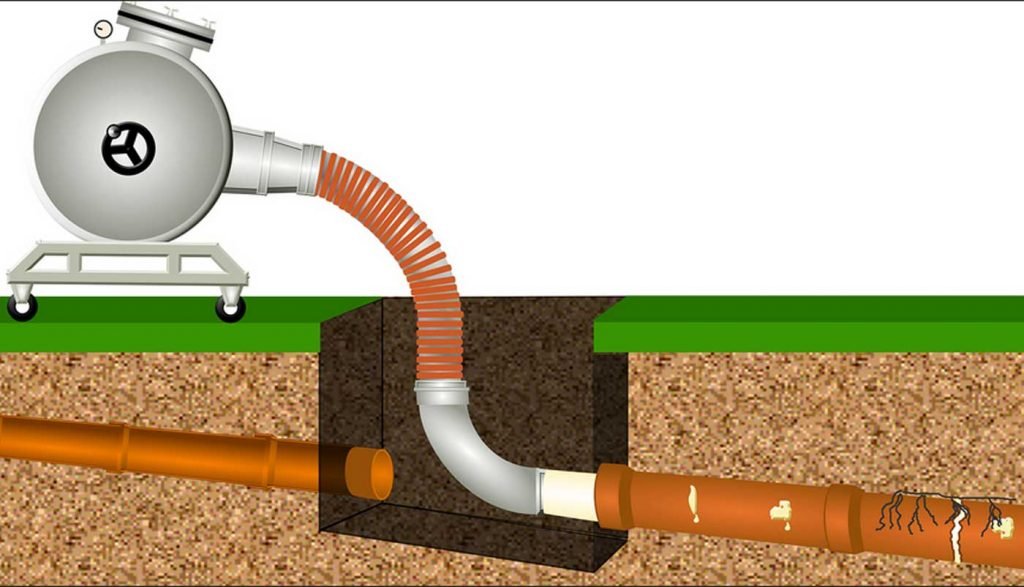

- Inversion – If you don’t want to deal with a blocked drain again, then this method is the best for you. Inversion is used to repair longer distances pipe, over 3 meters. It uses air pressure to invert a resin impregnated liner into an existing pipeline through an inversion drum; This is a high-quality piece of equipment that guarantees a 100% excellent result. The advantage of this method is the resin is applied on the outside, so it adheres to your existing pipe closing all the cracks and joints, ensuring tree roots have no chance of gaining access to the pipeline again.

- Patch Relining – Also known as sectional patch pipe relining, is best used when there is only a few or a single portion in the pipe that critically needs repairing or the property owner would like to fix only the severely affected areas. The cost is based on the number of patches installed, not per meter.

- Drag in – This method is used when the job is impossible to undertake with an inversion drum. However, it does come with risks and shorter life expectancies. The problem with this method is that the resin is installed on the inside of the liner, so the epoxy resin has no way to properly adhere to the existing pipe and seal cracks and joints that tree roots have gained access through. The other drawback of this method is that it requires two access points – one to feed the liner into and the other to pull the liner through, which may result in the additional excavation which will add up to the relining cost.

Final Words

When sewers break down, sometimes it is without warnings, or no words of caution, just an emergency that calls for urgent repair. It is where having knowledge of the repair and the cost comes into play. It will not only keep you from falling prey to companies that might take advantage of you but also give you an idea of what to expect during the repair. The bottom line is, no one wants to pay for something they don’t understand and need. So it goes a long way to know the matter.