Sometimes, it’s quite difficult to control and determine the accurate dimensions for bulk plastic parts and components that you produce with injection molding. However, you can always ensure the best control of the dimensional accuracy of your products by adjusting various aspects of your bulk plastic production beforehand, starting from the design right down to the manufacturing phase.

Can You Control Accurate Dimensions when You Produce Bulk Products with Plastic Molding?

The biggest challenge when you produce bulk plastic products using plastic molding is that you will come across dimensional accuracy problems from time to time. Yes, sometimes, you cannot determine the accuracy of each plastic part or component that you produce using this manufacturing process. There will always be some units that don’t get produced with the right dimensional accuracy as you intend them to be.

Now, the question of whether you can control accurate dimensions when you produce bulk plastic products will lead to different answers depending on your case. Dimensional accuracy can get mismatched because of various factors, such as the design of your plastic products, the materials you are using, the tooling for the products, and also the way you run the manufacturing production.

Tips to Apply Accurate Dimensions for Bulk Products

Sometimes, you might get a sense that there is always something wrong when you produce plastic products in bulk quantities using injection molding. For instance, material defects can happen. Or, you might get some problems like shrinkage and cracking.

To get a better control on how your plastic products will look, along with their dimensional measurements, it’s best to understand how to maintain accurate dimensions in your production of bulk plastic products.

Here are some tips to apply accurate dimensions for bulk products:

- Start with your design. To maintain the best accuracy for your bulk plastic products, your design is everything, as it will hold all the details about the product’s measurements. However, to keep the measurements as accurate as possible throughout the long production runs, you need to apply certain strategies in various aspects of your design, which include applying universal thickness for your product, avoid using thin long lines that will be subject to shrinkage, and so on.

- Keep in mind about potential shrinkage. Shrinkage will happen when you perform the injection molding of bulk plastic products, and it will cause various deformations in shapes of the products later. It’s best to pick the materials according to their shrinkage level and use only materials that can withstand shrinkage and keep their dimensional accuracy.

- Keep in mind about the low thickness parts. Some parts of your design with the low thickness can potentially shrink down and cause dimensional inaccuracy for your products. Maintaining a good thickness can help you with keeping the accurate dimensions for your bulk products.

- Choose better material grades. The material grades you use for the bulk manufacturing process can affect the results you will get for the plastic products, such as how it looks and how accurate the dimensional measurement is. Higher-grade materials can give you a higher injection molding cost, but it can also help you fix the dimensional accuracy for your bulk plastic products.

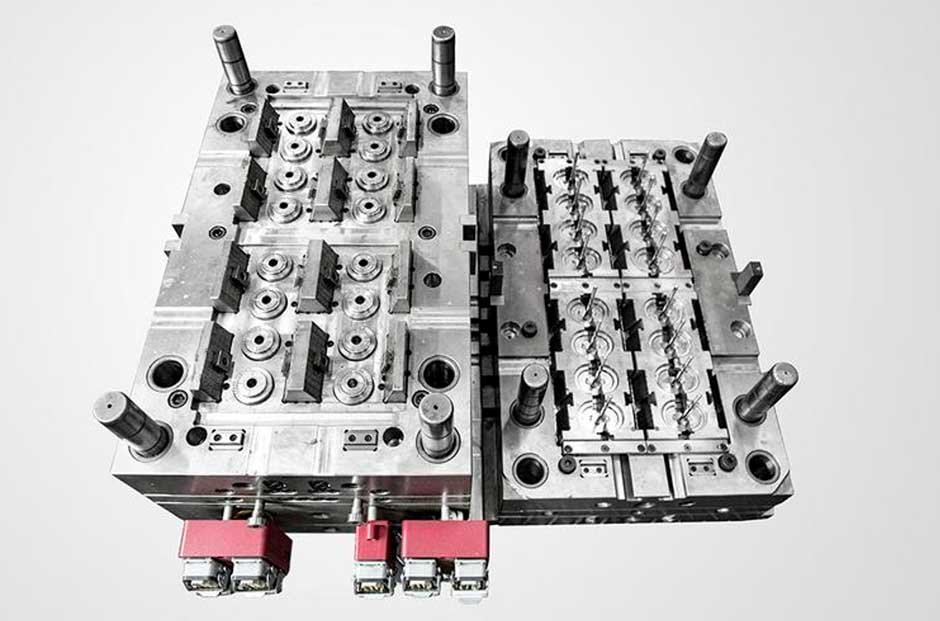

- Improve on your tooling. The tooling quality will also affect the results of your injection-molded products, so it is important for you to improve on it if you want to keep the plastic bulk products free from any dimensional inaccuracy. Please note that using intricate designs for your tooling might also contribute to the dimensional inaccuracy of the final products.

- Consult with expert molders. Those who are experts in the injection molding scene will be able to give you some valuable advice about how to keep the dimensional accuracy in your bulk production runs. You can also send your product prototype to a reliable injection molding service, so that they can devise a strategy to keep the accurate dimension for the products you will produce in bulk later.

Mistakes that Can Ruin Your Dimensional Accuracy for Bulk Production Runs

- Not considering the shrinkage potential. Most plastic materials will have the potential of shrinkage, and it means that your final products might get smaller than the initial dimensional measurements. It is important for you to consider the shrinkage potential, especially when you are producing plastic products in bulk, which will have higher instances of inaccuracies.

- Low quality plastic materials. Using low quality plastic materials will also put your final products into jeopardy, especially if your aim is to get the best dimensional accuracy for your bulk plastic products. With the low quality plastic materials, you can only expect the lowest quality products out of your injection molding processes.

- Intricate designs with too many thin parts. Injection molding supports complex geometries in your design, but the design that is too intricate and contains too many thin parts will only give you a higher risk of product defects and inaccuracy. It’s best to simplify your design and make sure that your plastic products still carry all the features you need.

- Bad tooling quality. The quality of the tooling you have will also affect the quality of the final products, especially when you are producing plastic parts and components in bulk. Using a cheap tooling will only produce cheap-quality bulk products with more chances of dimensional inaccuracy. So, it’s worth mentioning that your tooling quality is one of the most important keys for achieving best dimensional accuracy for your bulk products.

- Bad tooling materials. The materials you are using for the tooling process will also affect the quality of the tooling or mold you will get for the bulk plastic production. Use higher quality materials for your tooling process to get the best dimensional accuracy for your bulk plastic parts and components.

Conclusion

A good plastic molding company will always provide the best dimensional accuracy for the plastic parts and components you produce with the injection molding process. So, when you produce bulk plastic products for your clients, you will need to determine the various factors that ensure you will get the best dimensional accuracy for these plastic parts and components.

We at TEAM Rapid can provide you with the best injection molding services that can provide the best dimensional accuracy for your bulk plastic parts and components production.